|

Ningbo Jinyi Precision Machinery Co., Ltd.

|

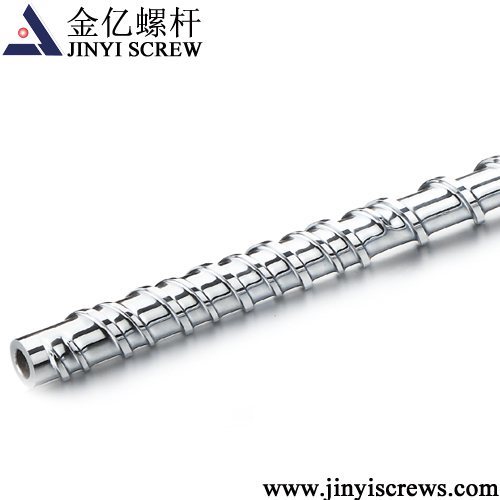

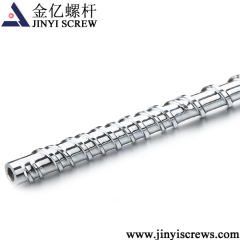

Barrier Type Mixing Element

| Price: | 10.0~500.0 USD |

| Payment Terms: | T/T,WU;Paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Better Mixing & Melting

No loss of pressure

Lower Melt Temperature

Introduction

Extruder feed-screw design, more than any other part of an extrusion system, determines the productivity and quality of the extruded product. Screw designers are constantly asked to improve output quantity without sacrificing quality, or to improve both at the same time. Barrier-type feed screws are the most widely used designs in high-output, high-quality extrusion. In applications that also require low melt temperature, such as blown film, they are the standard.

Barrier type screw designs are the most widely used screw designs in the extrusion industry. There are many different names for versions of this design by virtually all manufacturers and designers, However the basic part of the paten is common in all of these versions.

The advantages derived from properly designed barrier screws are improved rate, lower melt temperature, and improved melt quality. To fully enjoy these benefits, barrier screw designs normally incorporate a downstream mixing device.

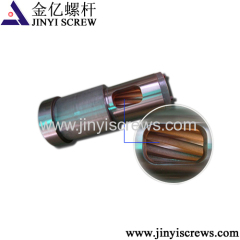

How it Works

With a barrier Screw, it seperate the melted & unmelted resins to avoid additional shear, behind the barrier section, both melted & unmelted reunion during the metering section

Avaialbe: 25-250mm Diameter